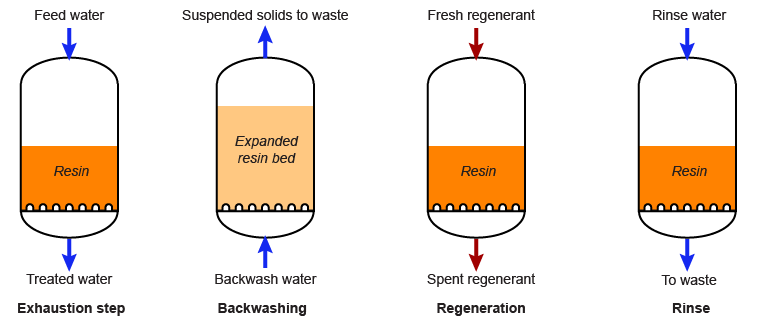

Complete cycle

of an ion exchange unit

In water treatment

The cycle of an ion exchange column used for water treatment consists of the following steps:

- Exhaustion (production) step

- Backwash

- Regeneration

- Rinse

The picture shows a cycle with co-flow regeneration.

Exhaustion step

The solution to be treated (feed water) passes through the ion exchange resin bed, exhausting the resin progressively. At the breakthrough point, i.e. at the point where the ion leakage reaches a pre-determined value, the exhaustion step is stopped.

Backwash

Before regeneration, the resin bed is backwashed

a) to loosen it and prevent excessive compaction

b) to remove accumulated suspended solid and possible broke resin particles from the bed surface

The bed expansion should be 50 to 100 % and the time of backwash is a few minutes.

Backwashing the resin bed is not performed in case of reverse flow regeneration so as not to disturb the distribution of resin layers, except whan the pressure drop increases excessively, or every 30 cycles or so.

Regeneration

The regenerant solution is then slowly introduced into the column. The regeneration time is usually 20 to 60 minutes. Full details about regeneration procedure are shown in a separate page.

Rinse

Rinsing the resin after regeneration is done in two steps:- Slow rinse or displacement. The regenerant must be displaced with water from the resin bed until only traces of the chemical are left. This displacement rinse is done at a low flow rate, the same as the regeneration flow rate.

- Final fast rinse. Finally, the resin bed is submitted to a fast rinse at service flow rate to remove the last traces of regenerant. The end of this final rinse is reached when the outlet water quality meets the treated water quality specification. With clean resins, the final rinsing time is around 20 minutes.

As the salinity of the outlet water produced during the rinsiing step is usually low, it is often convenient to recycle this water to the head of the system instead of discarding it to waste. In this way, the consumption of ancillary water is reduced, and the ionic load on the resin is also reduced, because you load less ions on the system than you would do using raw water.

Special applications

In several applications other than water treatment, the solution treated by resins must be displaced before regeneration, to recover as much treated solution as possible, avoiding losses in the regeneration waste. This additional step is called "sweetening-off" because it was first introduced in sugar treatment processes. Similarly, a "sweetening-on" step is carried out after regeneration and rinse before feeding the raw solution to be treated, to avoid dilution of the treated solution. The complete regeneration process consists then of the following steps:

- Backwash with the raw solution (optional)

- Sweetening-off: displacement of the solution with water

- Regenerant injection

- Displacement of the regenerant with water

- Fast rinse with water

- Sweetening-on with the solution to be treated