Overrunning a weak resin

What is overrun?

Overrunning is a concept used when two resins are used in a sequence, usually a weak and a strong resin. Overrunning consists of operating the first resin beyond its normal operating capacity, whereby a large part of the ionic load "leaks" onto the second resin.

When is it helpful?

Overrunning is useful:

- To utilise the capacity of a resin to its maximum extent

- To balance the resin volumes in a couple of weak and strong resin

- By passing the regenerant in thoroughfare, i.e. starting regeneration with the second resin, to ensure that it receives a maximum quantity of fresh regenerant and thus produces a very pure effluent.

Practical example

We will examine the concept of overrunning with the example of a couple of weak and strong anion exchange resins. Let us assume a water with the following anion composition, after de-cationisation and degasification:

| Cl | 3.00 meq/L (or eq/m3) |

| SO4 | 2.00 meq/L |

| CO2 | 0.25 meq/L |

| SiO2 | 0.25 meq/L |

The decationised water contains thus 10 times more strong acids (5 meq/L) than weak acids (0.5 meq/L). This is a very common case.

Assume now that you will use a combination of weak and strong base anion resins. They will have the following typical operating capacities (round numbers here for easy calculation; exact values from engineering data sheets or computer program):

| WBA | 1.0 eq/L |

| SBA | 0.5 eq/L |

Suppose you want to treat 100 m3/h of water with a service run of 10 hours, i.e. with a throughput of 1000 m3. You have decided to use a 2-compartment Amberpack Reverse or Upcore column. Your total ionic load in a run will be:

| Strong acids (Cl + SO4): | 1000 x 5.0 = 5000 eq |

| Weak acids (CO2 + SiO2): | 1000 x 0.5 = 500 eq |

Remembering that weak base resins exchange strong acids, and strong base resins exchange weak (as well as strong) acids, and considering the operating capacities mentioned above, you will need:

Remembering that weak base resins exchange strong acids, and strong base resins exchange weak (as well as strong) acids, and considering the operating capacities mentioned above, you will need:

| For the strong acids: | 5000/1.0 = 5000 litres of WBA resin |

| For the weak acids: | 500/0.5 = 1000 litres only of SBA resin |

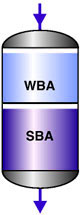

The resin volumes are quite different, and your Amberpack Reverse column would look like the first picture. Visibly very unbalanced. Calculating the specific flow rates for each resin (m3 of water per m3 of resin per hour), you would have:

| WBA | 100/5 = 20 BV/h |

| SBA | 100/1 = 100 BV/h |

this last number is higher than the recommended specific flow rate for SBA resins (usually limited to 40 or 50 BV/h). This solution is not acceptable: you need more SBA resin to meet the flow rate limit and to have a decent bed depth (preferably more than 1 m).

What you can do is make the WBA resin deliberately too small, e.g. with 3500 L only, so the ionic load will be 3500 eq instead of 5000 eq, and the SBA resin will have to treat the 500 eq of weak acids plus the remaining 1500 eq of strong acids, i.e. 2000 eq in total.

You will thus need (assuming the operating capacities have not changed):

You will thus need (assuming the operating capacities have not changed):

| WBA | 3500/1.0 = 3500 L | = 3.5 m3 |

| SBA | 2000/0.5 = 4000 L | = 4.0 m3 |

The volumes are now similar, and the specific flow rates are:

| WBA | 100/3.5 = 28.6 BV/h |

| SBA | 100/4.0 = 25.0 BV/h |

both are within the recommended range of specific flow rate, and the Amberpack Reverse column looks like the second picture, where volumes are visibly much better balanced.

By transferring 1500 eq of the total 5000 eq of strong acids (i.e. 30%) you have overrun the WBA resin by 30%. In reality, you have achieved three additional benefits:

- By overrunning the WBA resin, you have utilised more than the initial 1.0 eq/L, getting close to the total capacity of the resin.

- By increasing the volume of SBA resin, you have decreased the silica load, which is 250 eq per run, and was initially 0.25 eq per litre of SBA resin, and now 250/4 = 0.0625 eq/L. One of the rules to avoid silica fouling is to limit the silica load to less than 0.2 eq/L.

- By decreasing the silica to total anions in the feed to the SBA, you have increased its operating capacity.

With the increased capacity values, your final volumes will be less than shown in our rough calculation.

Regeneration

Regeneration is always done in thoroughfare, i.e. the regenerant passes first through the strong, then through the weak resin. The degree of overrun does not change the global regeneration conditions or regenerant quantity.

WAC/SAC resin pairs

The same reasoning applies, but the case is less frequent, unless the m-alkalinity in your water is more than about 60% of the anions and the hardness more than 65% of the cations. You often end up with a smaller WAC resin volume.