Ion exchange resin properties

Introduction

We will examine the meaning of

We will examine the meaning of

- Particle size

- Capacity

- Moisture

- Dry matter

- Specific gravity

- Bulk density

- Effect of bed compression

- Optical aspect

- Resin volume and swelling

- Stability

- Structure and selectivity

and examples will be shown.

The structure (matrix and functional groups) of ion exchange resins is described in other pages, as well as details of total and operating ion exchange capacity.

The importance of ionic form

In expressing the results of most resin properties, the ionic form should always be mentioned, as the values are different according to the ions in the resin beads. This applies in particular to the following properties:- Capacity

- Moisture

- Density

and to a lesser extent to the particle size. For example, Amberjet 4400 has a total capacity of about 1.5 eq/L in the Cl— form and 1.2 eq/L in the OH— form. The difference is just due to resin swelling: it swells by up to 30 % between the Cl— and the OH— form. The number of active groups in a resin sample is obviously constant, so that when the resin swells, the density of these active groups decreases, and the volume capacity is a measure of this active groups density.

Example: analysis of a batch of new resin

| Resin type | Amberlite IRA96 |

|---|---|

| Lot number | 6210AA55 |

| Volume capacity [free base form] | 1.36 eq/L |

| Dry weight capacity [free base] | 5.16 eq/kg |

| Dry matter [free base] | 264 g/L |

| Strongly basic capacity | 8.6 % |

| Moisture holding capacity [free base] | 61.8 % |

| Perfect beads | 98 % |

| Whole beads | 99 % |

| Specific gravity [free base] | 1.04 |

| Particle size | |

| Mean diameter | 0.68 mm |

| Uniformity coefficient | 1.34 |

| Harmonic mean size | 0.67 mm |

| Effective size | 0.53 mm |

| Fines through 0.300 mm | 0.1 % |

| Coarse beads on 1.18 mm | 0.2 % |

Particle size distribution

Traditionally, the particle size distribution of a resin was measured using a set of sieves. The volume on the resin fraction remaining on each sieve is measured in a glass cylinder. It was found practical to express the results in cumulative percentage through a given sieve opening.Today, granulometry is measured with particle counters which are linked to a computer and calculate all particle size parameters. The components of a particle size distribution are:

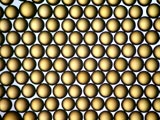

Uniform resin

UC = 1.07

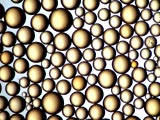

Conventional resin

UC = 1.60

- Mean diameter

- Uniformity coefficient

- Effective size

- Harmonic mean size

- Quantity of fine beads

- Quantity of big beads

Measuring particle size

Example of traditional analysis measuring the volume of resin retained on each sieve:

Example of traditional analysis measuring the volume of resin retained on each sieve:

| mm | % retained on sieve | % through sieve |

|---|---|---|

| 1.25 | 0.8 | 99.2 |

| 1.00 | 2.0 | 97.2 |

| 0.80 | 14.9 | 82.3 |

| 0.63 | 33.2 | 49.1 |

| 0.50 | 32.5 | 16.6 |

| 0.40 | 14.1 | 2.5 |

| 0.315 | 2.0 | 0.5 |

| Finer | 0.5 |

The values "between sieves" have been plotted on a graph with a logarithmic scale for the sieve openings. In theory, and very roughly in practice as well, the particle size distribution of conventional "kettle polymerised" resins is normal, or Gaussian. A Gaussian bell curve has been superimposed on the graph.

Definitions

- The mean diameter is the value of the (theoretical) sieve opening through which exactly 50 % of the resin volume passes, i.e. that retains exactly 50 % of the resin sample. It is abbreviated as "d50". In the language of statistics, it is called median diameter.

- The effective size is the value of the sieve opening through which exactly 10 % of the resin sample passes. It is abbreviated as "d10".

- The uniformity coefficient is defined as: UC = d60 / d10

This coefficient measures the "width" of the distribution, and is reflected in the width of the Gaussian bell curve. If all beads had the same size, it would be equal to 1.0. Amberjet resins have a UC of 1.05 to 1.20, Ambersep and SB grades 1.15 to 1.30, RF grades 1.20 to 1.50, standard grades 1.3 to 1.7. See the small pictures above. -

The harmonic mean size abbreviated as HMS is a mathematical expression calculated from the distribution function.

See the formula on the right. HMS is useful for theoretical considerations regarding hydraulic properties and kinetics of a resin. For practical purposes, the value of HMS is close to the median diameter, but a little smaller. Both values are almost identical for resins with uniform particle size.

See the formula on the right. HMS is useful for theoretical considerations regarding hydraulic properties and kinetics of a resin. For practical purposes, the value of HMS is close to the median diameter, but a little smaller. Both values are almost identical for resins with uniform particle size.

Using a Gaussian-logarithmic paper, a normal distribution (cumulated percentage through the sieves) will appear as a straight line, as shown on the picture here. In the past, this paper was used to calculate mean diameter, effective size and uniformity coefficient based on the laboratory results. This example displays the results corresponding to the bell curve above. The points are not exactly aligned due to imprecision in the sieving, and due to the fact that the actual distribution is not exactly Gaussian. The characteristic values for this example are:

Using a Gaussian-logarithmic paper, a normal distribution (cumulated percentage through the sieves) will appear as a straight line, as shown on the picture here. In the past, this paper was used to calculate mean diameter, effective size and uniformity coefficient based on the laboratory results. This example displays the results corresponding to the bell curve above. The points are not exactly aligned due to imprecision in the sieving, and due to the fact that the actual distribution is not exactly Gaussian. The characteristic values for this example are:

| Mean (median) diameter | 0.640 mm |

| Uniformity coefficient | 1.53 |

| Effective size | 0.449 mm |

| Harmonic mean size | 0.616 mm |

For resins with uniform particle size, the median diameter, harmonic mean size and effective size are close to each other. They would be identical for resins totally uniform, i.e. with a uniformity coefficient equal to 1.00. See the bell curve and the Gaussian-logarithmic plot for a resin with uniformity coefficient 1.10.

What particle size means

Fine resin- Good kinetics (fast exchange rate)

- High pressure drop

- Low pressure drop

- No problem with clogging collectors

Bead size is important

- for mixed beds

- for stratified beds

- for packed beds

- for fluidised beds

- for backwashing

- for chromatography

- fine resins have higher kinetics

In the USA, particle size is often expressed in mesh. See a table of correspondence.

Ion exchange capacity

Total capacity- This is the number of active groups

- i.e. the number of exchangeable monovalent ions

Operating capacity

- This is the number of sites where exchange actually takes place during one cycle

Total capacities of new resins are measured for quality control. Capacities are expressed in equivalents per litre of wet resin or in equivalents per kilogramme of dried resin. The dry weight capacity indicates if a resin has been properly functionalised, irrespective of its water content. Whilst a high total capacity is generally desirable, not all exchange sites are used in a complete ion exchange cycle. Details on the concept of total and operating capacity are presented in another page.

Moisture holding capacity

Moisture (water retention, or water content) is related to porosity and ionic form. The water content is expressed as a percentage of the moist resin weight in a given ionic form. Here is the influence of porosity on resin performance:High moisture

- fast exchange

- good adsorption properties

- low total capacity

- high total capacity

- difficult to regenerate

- no removal of big ions

- tendency to fouling

About half the weight of all ion exchange resins is water, unless they have been dried or the water has been replaced with an organic solvent. The water surrounds the active groups (hydration water) and fills the voids in the resin matrix. Obviously, a resin with high moisture has less dry matter, therefore less active groups and less capacity; but on the other hand, such a resin may provide easier access for large ions into its structure.

For gel resins, the amount of water is inversely related to the degree of crosslinking of the matrix. This is not true for macroporous resins, because their (artificial) macroporosity can be varied as a parameter independent from crosslinking. See the "resin structure" page.

Usually, low moisture resins have a slower exchange rate and are more susceptible to fouling than high moisture resins.

Dry matter

The dry matter is calculated:- either as the complement of moisture holding capacity (in %);

- or as a weight of dry resin per litre of resin as delivered (in g/L)*.

The dry matter was used in the past by some manufacturers instead of the percentage of moisture retention. Today, the dry matter concept is not much used any more.

Specific gravity (true bead density)

Density is important for- Mixed bed separation

- Stratified beds (Stratabed)

- Floating beds

- Backwashing

Although not an item for routine testing, specific gravity is an important parameter for successful plant operation. It is critical for all processes involving mixing or separation of 2 or 3 resins in the same column, and for adjustment of resin backwash flow rate.

Measurement of the specific gravity is made with a pycnometre.

Note that specific gravity varies with the ionic form of the resin. The ionic composition of a resin varies all the time during a cycle, so it is difficult to predict the exact specific gravity. This is important to understand when backwashing a resin bed.

Here are some typical values:

| Resin type | Ionic form | Density range | Typical |

| WAC | H | 1.16 to 1.19 | 1.18 |

| WAC | Ca | 1.28 to 1.34 | 1.32 |

| SAC | H | 1.18 to 1.22 | 1.20 |

| SAC | Na | 1.26 to 1.32 | 1.28 |

| SAC | Ca | 1.28 to 1.33 | 1.31 |

| WBA | Free base | 1.02 to 1.05 | 1.04 |

| WBA | Cl | 1.05 to 1.09 | 1.06 |

| WBA | SO4 | 1.08 to 1.13 | 1.11 |

| SBA | OH | 1.06 to 1.09 | 1.07 |

| SBA | Cl | 1.07 to 1.10 | 1.08 |

| SBA | SO4 | 1.10 to 1.14 | 1.12 |

Bulk density and shipping weight

The bulk density of a resin is usually expressed as the mass of one litre of the resin. As there are small variations of bulk density from batch to batch, a standard value, called shipping weight, is used for packaging the resin in the production plant. The variations of bulk density are mainly due to residual water in the bulk resin after removal of the interstitial water on the draining belt just before packaging.

Example:

Assume the bulk density values for a given resin type have a range of 720 to 780 g/L. Setting the shipping weight at 770 g/L will have the following results:

- Each 25 L bag will contain 0.770 x 25 = 19.25 kg resin.

- If the resin lot has a bulk density of 720 g/L, which is 1.389 L/kg, the customer will receive 19.25 x 1.389 = 26.7 L resin in a 25 L bag.

- If the resin lot has a bulk density of 780 g/L, which is 1.282 L/kg, the customer will receive 19.25 x 1.282 = 24.7 L resin in a 25 L bag.

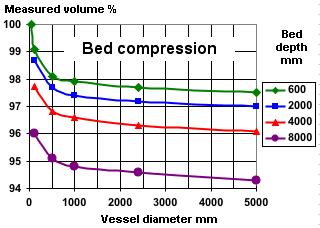

Bed compression

The picture here has been measured by a customer who was not sure if the delivered resin volume was correct.

Optical aspect

Optical aspect of a used resin

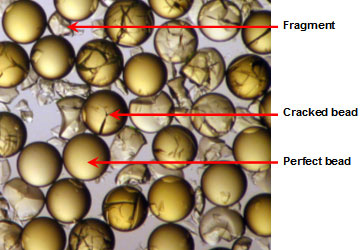

The optical aspect of a new resin, i.e. the number of cracked beads and fragments, is an important part of resin quality control in production. The quality control methods use the concept of perfect beads and whole beads. Perfect beads are just perfect, i.e. not cracked, not broken. Whole beads are spherical, i.e. not a fragment, but can be cracked.

For samples of used resins, the aspect can give valuable information about operating problems. So for instance in a used sample the following values are reported:

| PBC (perfect bead count) | 65 % |

| WBC (whole bead count) | 94 % |

This means that the sample has:

- 65 % perfect beads

- 29 % cracked beads

- 6 % fragments

See pictures of new resin samples.

Ionic form and volume change

Resins change volume according to the ions loaded on them. For instance, a gel type strongly basic resin may swell by more than 25 % if it is totally converted from the chloride form (as delivered) to the hydroxide form.Here are the most usual ionic forms of delivery for resins used in water treatment, and an idea about their volume change.

| Resin type | Ionic form as supplied | Total volume change | From...To | Example |

|---|---|---|---|---|

| SAC | Na, H | 6 to 10 % | Na to H | Amberjet 1000 |

| SBA | Cl, OH, SO4 | 15 to 30 % 6 to 10 % |

Cl to OH Cl to SO4 |

Amberjet 4200 |

| WBA | Free base (FB) | 10 to 25 % | FB to Cl | Amberlite IRA96 |

| WAC | H | 15 to 40 % 60 to 100 % |

H to (Ca+Mg) H to Na |

Amberlite IRC86 |

More accurate data about resin swelling are usually available in the individual product data sheets published by the resin producers.

The volume change is due to the different hydration state of the ions in the resin: for instance, weak resins are almost not dissociated in regenerated form, so there are no free ions in the resin beads. Once they have exchanged ions, though, these ions are hydrated:

Resins are rarely fully converted from 100 % regenerated to 100 % exhausted, so in general the maximum theoretical volume change is not achieved. However, a volume change does take place in operation, and is visible if you watch the resin bed surface in a column before and after regeneration. This is important in the case of packed beds where there is almost no freeboard.

Stability

Resins must withstand various forms of stress in operation:- Physical stress in case of resin transfer or high pressure drop

- Osmotic stress due to the change in volume (see above)

- Thermal stress in case high temperature or temperature variations

- Organic fouling